Revolutionizing Warehouse Efficiency: Understanding Warehouse Management Software Systems

In today’s fast-paced world of e-commerce and global supply chains, efficient warehouse operations are no longer a luxury but a necessity. A critical component in achieving this efficiency is the implementation of a robust warehouse management software system. This system acts as the central nervous system of a warehouse, orchestrating everything from receiving and putaway to picking, packing, and shipping. Businesses seeking to optimize their supply chain and enhance customer satisfaction are increasingly turning to these sophisticated solutions.

What is a Warehouse Management Software System?

A warehouse management software system (WMS) is a software application designed to support and optimize warehouse functionality and distribution center management. These systems provide real-time visibility of your entire inventory and manage warehouse operations from the moment goods or materials enter the warehouse until they move out. It’s more than just inventory tracking; it’s about streamlining processes, reducing errors, and improving overall productivity.

At its core, a warehouse management software system aims to improve efficiency by:

- Optimizing space utilization.

- Streamlining workflows.

- Reducing labor costs.

- Minimizing errors.

- Improving inventory accuracy.

- Enhancing customer service.

Key Features of a Warehouse Management Software System

Modern warehouse management software systems boast a wide array of features designed to address the complexities of warehouse operations. Some of the most crucial features include:

Inventory Management

This is the foundation of any WMS. It provides real-time visibility into inventory levels, locations, and movements. Advanced systems offer features like cycle counting, lot tracking, and expiration date management. Accurate inventory management is crucial for minimizing stockouts and overstocking. Using a warehouse management software system can help businesses to improve their inventory control.

Receiving and Putaway

The WMS guides the receiving process, ensuring that goods are accurately identified, inspected, and recorded upon arrival. It then directs the putaway process, optimizing storage locations based on factors like product velocity, size, and accessibility. The goal is to minimize travel time and maximize space utilization. An efficient warehouse management software system makes this process seamless.

Order Management

The order management module manages the entire order fulfillment process, from order entry to shipping. It prioritizes orders, allocates inventory, and generates picking lists. Advanced systems integrate with e-commerce platforms and other business systems to automate order processing. Good order management is a sign of a high-quality warehouse management software system.

Picking and Packing

This is where the WMS truly shines. It optimizes picking routes, directs pickers to the most efficient locations, and minimizes travel time. It also supports various picking methods, such as wave picking, zone picking, and batch picking. The packing module ensures that orders are accurately packed and labeled for shipment. The right warehouse management software system can dramatically improve picking and packing speeds.

Shipping and Transportation Management

The WMS integrates with shipping carriers to generate shipping labels, track shipments, and manage transportation costs. It also supports various shipping methods, such as LTL (Less-than-Truckload) and FTL (Full Truckload). Efficient shipping is a key component of customer satisfaction, and a warehouse management software system facilitates this.

Reporting and Analytics

A robust reporting and analytics module provides valuable insights into warehouse performance. It tracks key performance indicators (KPIs) such as order fulfillment rates, inventory turnover, and labor productivity. This data can be used to identify areas for improvement and optimize warehouse operations. This is a critical tool offered by every warehouse management software system.

Benefits of Implementing a Warehouse Management Software System

The benefits of implementing a warehouse management software system are numerous and can significantly impact a company’s bottom line. Here are some of the most significant advantages:

- Increased Efficiency: By automating and streamlining warehouse processes, a WMS can significantly improve efficiency and productivity.

- Reduced Costs: Optimized workflows, reduced errors, and improved inventory management lead to significant cost savings.

- Improved Inventory Accuracy: Real-time visibility into inventory levels minimizes stockouts and overstocking, leading to reduced inventory holding costs.

- Enhanced Customer Satisfaction: Faster order fulfillment, accurate shipments, and improved communication lead to happier customers.

- Better Space Utilization: Optimized storage locations and efficient putaway processes maximize space utilization, reducing the need for additional warehouse space.

- Improved Labor Productivity: Streamlined workflows and optimized picking routes improve labor productivity, allowing employees to focus on more value-added tasks.

- Data-Driven Decision Making: Comprehensive reporting and analytics provide valuable insights into warehouse performance, enabling data-driven decision making.

Choosing the Right Warehouse Management Software System

Selecting the right warehouse management software system is a critical decision that requires careful consideration. Here are some factors to keep in mind:

Business Needs

The first step is to clearly define your business needs and objectives. What are your biggest warehouse challenges? What specific features are most important to you? A thorough understanding of your requirements will help you narrow down your options. A warehouse management software system must be tailored to your business.

Scalability

Choose a system that can scale with your business. As your company grows, your WMS should be able to handle increasing volumes and complexity. A scalable warehouse management software system is a long-term investment.

Integration

Ensure that the WMS integrates seamlessly with your other business systems, such as your ERP (Enterprise Resource Planning) system, CRM (Customer Relationship Management) system, and e-commerce platform. Seamless integration is crucial for data accuracy and efficiency. A good warehouse management software system will integrate easily with existing systems.

User-Friendliness

The WMS should be easy to use and intuitive. A user-friendly interface will minimize training time and improve user adoption. Employee training is essential for the effective use of a warehouse management software system.

Vendor Reputation

Choose a reputable vendor with a proven track record of success. Read reviews, talk to other customers, and ask for references. A reliable vendor is essential for long-term support and maintenance. Picking the right vendor for your warehouse management software system is crucial.

Cost

Consider the total cost of ownership, including software licensing fees, implementation costs, training costs, and ongoing maintenance costs. Don’t just focus on the upfront cost; consider the long-term value. Consider the ROI of your warehouse management software system investment.

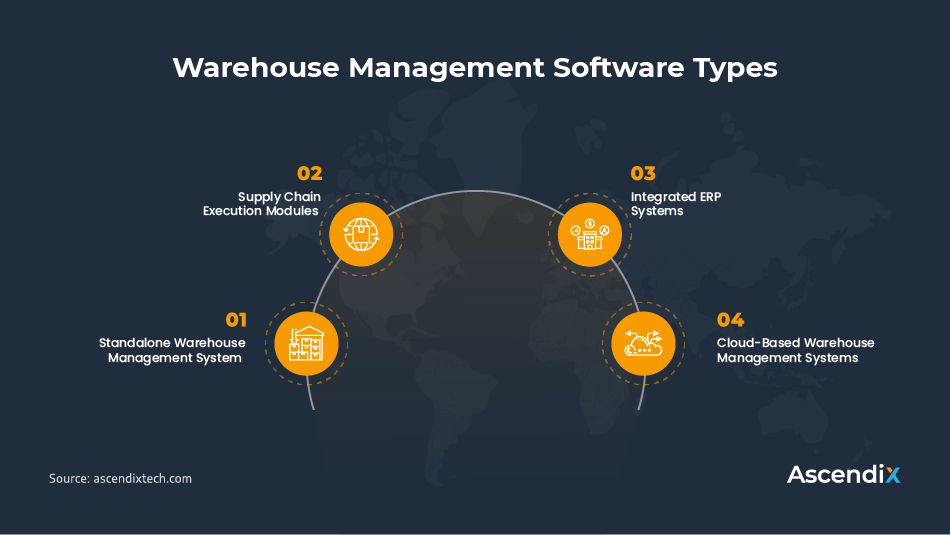

Types of Warehouse Management Software Systems

Warehouse management software systems come in various forms, each catering to different needs and business sizes. Understanding the different types can help you make a more informed decision.

Cloud-Based WMS

Cloud-based WMS solutions are hosted on the vendor’s servers and accessed via the internet. This eliminates the need for on-premise hardware and IT infrastructure, making them a cost-effective option for small and medium-sized businesses. Cloud-based systems offer scalability, flexibility, and automatic updates. Many companies now choose a cloud-based warehouse management software system.

On-Premise WMS

On-premise WMS solutions are installed on your own servers and require you to manage the hardware, software, and IT infrastructure. This option provides greater control over your data and security, but it also requires a significant upfront investment and ongoing maintenance. An on-premise warehouse management software system may be best for companies with specific security or compliance requirements.

Standalone WMS

Standalone WMS solutions are designed to manage warehouse operations independently of other business systems. While they can be a good option for small businesses with simple warehouse operations, they may not be suitable for larger companies that require integration with other systems. A standalone warehouse management software system is often less expensive but may lack advanced features.

Integrated WMS

Integrated WMS solutions are designed to integrate seamlessly with other business systems, such as ERP and CRM. This provides a holistic view of your entire supply chain and enables better coordination between different departments. An integrated warehouse management software system is ideal for larger companies with complex supply chains.

The Future of Warehouse Management Software Systems

The future of warehouse management software systems is bright, with advancements in technology driving innovation and transforming warehouse operations. Some of the key trends shaping the future of WMS include:

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML are being used to optimize warehouse processes, predict demand, and automate tasks.

- Robotics and Automation: Robots and automated systems are being used to perform tasks such as picking, packing, and sorting, improving efficiency and reducing labor costs.

- Internet of Things (IoT): IoT devices are being used to track inventory, monitor equipment, and optimize warehouse conditions.

- Augmented Reality (AR): AR is being used to provide workers with real-time information and guidance, improving accuracy and efficiency.

- Blockchain Technology: Blockchain is being used to improve supply chain transparency and security.

In conclusion, a warehouse management software system is an essential tool for businesses looking to optimize their warehouse operations, reduce costs, and improve customer satisfaction. By carefully considering your business needs and choosing the right system, you can unlock significant benefits and gain a competitive edge in today’s demanding marketplace. [See also: Inventory Management Best Practices] Investing in the right warehouse management software system can transform your warehouse from a cost center into a strategic asset.