Unveiling the Origins: Where Were Motorola Phones Made?

Motorola, a name synonymous with telecommunications innovation, holds a significant place in the history of mobile phones. From pioneering the first commercially available cellular phone to navigating the complexities of the smartphone era, Motorola’s journey is a testament to its enduring impact. But a question often arises: where were Motorola phones made? Understanding the manufacturing footprint of this iconic brand provides valuable insights into its global operations and supply chain strategies.

A Historical Perspective on Motorola’s Manufacturing

Motorola’s manufacturing history is as diverse as its product portfolio. Initially, the company’s production was heavily concentrated in the United States. As demand grew and the company expanded its global reach, Motorola established manufacturing facilities in various locations around the world. This shift reflects a common trend among multinational corporations seeking to optimize production costs and tap into new markets.

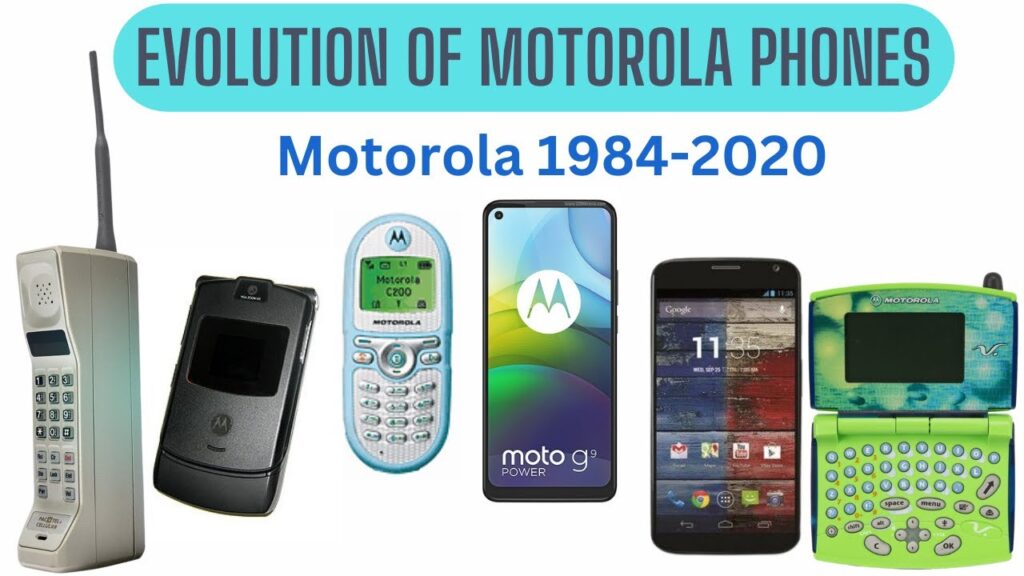

Early Motorola phones, including the groundbreaking DynaTAC, were primarily manufactured in the US. These early devices were expensive to produce, reflecting the high cost of labor and materials at the time. As technology advanced and competition intensified, Motorola began to explore alternative manufacturing locations to remain competitive. This strategic decision led to the establishment of factories in countries with lower labor costs and favorable manufacturing environments.

Key Manufacturing Locations Over the Years

Over the decades, Motorola phones were made in several key locations worldwide. These include:

- United States: Initially, the primary manufacturing hub. While production has shifted over time, some R&D and specialized manufacturing may still occur in the US.

- China: A major manufacturing center for many electronics companies, including Motorola. China’s vast manufacturing infrastructure and skilled workforce make it an attractive location for mass production.

- Brazil: Motorola established a significant presence in Brazil to serve the Latin American market. Manufacturing in Brazil allowed the company to reduce import costs and respond more quickly to local demand.

- India: As India’s mobile market exploded, Motorola, like many other manufacturers, established facilities there to cater to the growing demand. This move also helped Motorola to take advantage of government incentives and lower labor costs.

- Other Locations: Throughout its history, Motorola has also utilized manufacturing facilities in other countries, including Mexico and various European nations, depending on specific product lines and market needs.

The Impact of Lenovo’s Acquisition

In 2014, Lenovo acquired Motorola Mobility from Google. This acquisition significantly impacted Motorola’s manufacturing operations. Lenovo, a Chinese multinational technology company, already had a well-established global manufacturing footprint. Following the acquisition, Lenovo integrated Motorola’s manufacturing processes into its existing infrastructure. This integration led to further shifts in production locations, with a greater emphasis on Lenovo’s established manufacturing hubs, particularly in China.

Today, most Motorola phones are made in facilities operated by Lenovo or its manufacturing partners. While the Motorola brand continues to exist, the underlying manufacturing processes are now largely managed by Lenovo. This shift has allowed for greater efficiency and cost optimization, but it has also altered the geographical distribution of Motorola’s manufacturing operations.

Factors Influencing Manufacturing Location Decisions

Several factors influence where Motorola phones are made. These include:

- Labor Costs: Countries with lower labor costs offer a significant advantage for mass production.

- Manufacturing Infrastructure: The availability of advanced manufacturing facilities, skilled labor, and supporting industries is crucial.

- Government Incentives: Governments often offer incentives, such as tax breaks and subsidies, to attract manufacturers.

- Proximity to Markets: Manufacturing closer to key markets can reduce transportation costs and lead times.

- Supply Chain Efficiency: Access to a reliable and efficient supply chain is essential for timely production.

- Trade Agreements: Trade agreements between countries can impact tariffs and other trade barriers, influencing manufacturing decisions.

The Future of Motorola Phone Manufacturing

The future of Motorola phone manufacturing will likely continue to be shaped by factors such as technological advancements, global economic trends, and geopolitical considerations. As automation and robotics become more prevalent, the importance of low labor costs may diminish, potentially leading to a reshoring of some manufacturing activities. However, the established manufacturing infrastructure in countries like China will likely remain a significant advantage.

Furthermore, the ongoing trade tensions between the United States and China could lead to further diversification of manufacturing locations. Companies may seek to establish manufacturing facilities in countries that are less affected by these trade disputes. This could result in a more geographically dispersed manufacturing footprint for Motorola phones and other electronic devices.

Understanding the Supply Chain

The manufacturing location is only one part of the complex supply chain that brings Motorola phones to consumers. The supply chain includes the sourcing of components, assembly, testing, packaging, and distribution. Understanding this entire process provides a more complete picture of how Motorola phones are made and delivered to customers worldwide.

Component sourcing is a critical aspect of the supply chain. Motorola relies on a global network of suppliers for components such as processors, displays, memory chips, and camera modules. These components are often manufactured in different countries and then shipped to the assembly location. Efficient logistics and supply chain management are essential for ensuring that components arrive on time and that production schedules are met.

The Role of Contract Manufacturers

In addition to its own manufacturing facilities, Motorola also relies on contract manufacturers to produce some of its phones. Contract manufacturers are companies that specialize in providing manufacturing services to other businesses. By outsourcing production to contract manufacturers, Motorola can reduce its capital investment and gain access to specialized expertise and resources.

Foxconn and Pegatron are two of the largest contract manufacturers in the world. These companies have extensive manufacturing facilities in China and other countries and produce a wide range of electronic devices for various brands, including Motorola. The use of contract manufacturers allows Motorola to scale its production capacity quickly and efficiently in response to changing market demand.

The Impact of Manufacturing on Phone Quality

The manufacturing location and processes can have a significant impact on the quality of Motorola phones. Stringent quality control measures are essential for ensuring that phones meet the required standards. These measures include rigorous testing of components, assembly processes, and finished products.

Motorola and its manufacturing partners employ various quality control techniques to identify and address potential issues. These techniques include statistical process control, failure analysis, and root cause analysis. By continuously monitoring and improving its manufacturing processes, Motorola strives to deliver high-quality phones to its customers.

The Evolution of Motorola’s Manufacturing Strategy

Motorola’s manufacturing strategy has evolved significantly over the years in response to changing market conditions and technological advancements. From its early focus on domestic production to its current reliance on global manufacturing networks, Motorola has consistently adapted its approach to remain competitive.

The acquisition by Lenovo marked a significant turning point in Motorola’s manufacturing history. Lenovo’s established manufacturing infrastructure and expertise have enabled Motorola to achieve greater efficiency and cost optimization. However, the integration of Motorola’s manufacturing processes into Lenovo’s existing operations has also led to changes in the geographical distribution of production.

Consumer Perceptions of Manufacturing Locations

Consumer perceptions of manufacturing locations can influence purchasing decisions. Some consumers may prefer products that are made in certain countries, while others may be more concerned about price and features. Understanding these perceptions is important for Motorola and other manufacturers as they make decisions about where to produce their phones.

While some consumers may associate products made in China with lower quality, others recognize that many high-quality products are manufactured there. Motorola strives to ensure that its phones meet the required quality standards regardless of where they are made. By focusing on quality control and continuous improvement, Motorola aims to build trust with its customers and maintain its reputation for producing reliable and innovative phones. [See also: Motorola Phone Reviews]

The Future of Mobile Phone Manufacturing

The mobile phone manufacturing industry is constantly evolving. New technologies, changing consumer preferences, and geopolitical factors are all shaping the future of the industry. As manufacturers strive to remain competitive, they will need to adapt their manufacturing strategies to meet these challenges.

Automation, artificial intelligence, and the Internet of Things are all expected to play an increasingly important role in mobile phone manufacturing. These technologies can help manufacturers to improve efficiency, reduce costs, and enhance quality. By embracing these advancements, Motorola can position itself for continued success in the dynamic mobile phone market. Understanding where Motorola phones were made, and are made, provides a crucial context for understanding the company’s evolution.