Optimizing Efficiency: A Comprehensive Guide to Management Warehouse Systems

In today’s fast-paced business environment, efficient warehouse management is no longer a luxury but a necessity. A robust management warehouse system is the backbone of a streamlined supply chain, impacting everything from order fulfillment to customer satisfaction. This article delves into the intricacies of management warehouse systems, exploring their components, benefits, implementation strategies, and future trends. Whether you are a seasoned logistics professional or just beginning to explore the world of warehouse optimization, this guide will provide you with valuable insights to enhance your operations and achieve peak efficiency.

Understanding the Core Components of a Management Warehouse System

A management warehouse system isn’t a single piece of software; it’s a holistic approach encompassing various interconnected elements. These components work synergistically to ensure seamless operations from the moment goods arrive until they are shipped out.

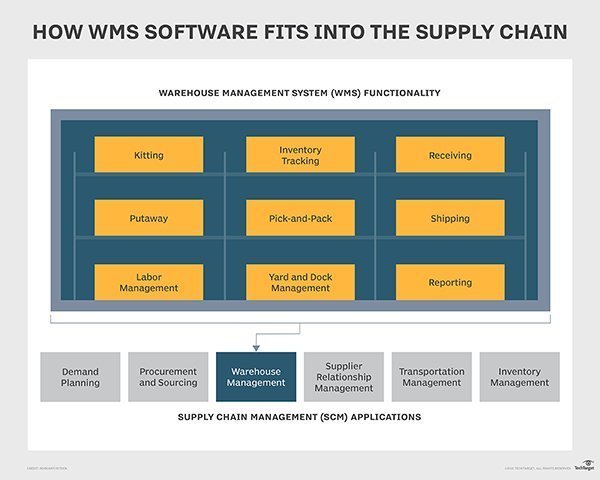

Warehouse Management System (WMS) Software

At the heart of any effective management warehouse system lies the WMS software. This software serves as the central nervous system, controlling and coordinating all warehouse activities. Key functionalities include:

- Inventory Management: Real-time tracking of inventory levels, locations, and movements.

- Receiving and Put-Away: Efficiently processing incoming shipments and allocating storage locations.

- Order Management: Prioritizing and managing orders for optimal fulfillment.

- Picking and Packing: Streamlining the retrieval and packaging of items for shipment.

- Shipping and Delivery: Coordinating with carriers and generating shipping documents.

- Reporting and Analytics: Providing insights into warehouse performance through data analysis.

Warehouse Layout and Design

The physical layout of your warehouse significantly impacts efficiency. A well-designed warehouse minimizes travel time, optimizes storage space, and facilitates smooth material flow. Consider factors such as:

- Storage Systems: Selecting appropriate storage solutions like pallet racking, shelving, or automated storage and retrieval systems (AS/RS).

- Aisle Widths: Ensuring sufficient space for forklifts and other equipment to maneuver.

- Dock Layout: Optimizing dock configuration for efficient loading and unloading.

- Material Flow: Designing a layout that minimizes backtracking and bottlenecks.

Equipment and Technology

Investing in the right equipment and technology is crucial for maximizing warehouse efficiency. This includes:

- Forklifts and Material Handling Equipment: Choosing the right equipment for your specific needs.

- Barcode Scanners and RFID Technology: Enabling accurate and efficient data capture.

- Conveyor Systems: Automating the movement of goods within the warehouse.

- Warehouse Automation Systems: Implementing robotic solutions for tasks such as picking and packing.

People and Processes

Even the most advanced management warehouse system relies on skilled personnel and well-defined processes. This includes:

- Training and Development: Equipping employees with the knowledge and skills to operate the system effectively.

- Standard Operating Procedures (SOPs): Establishing clear guidelines for all warehouse activities.

- Performance Management: Monitoring employee performance and providing feedback.

- Safety Protocols: Ensuring a safe working environment for all employees.

The Benefits of Implementing a Management Warehouse System

A well-implemented management warehouse system offers a multitude of benefits that can significantly impact your bottom line. Some key advantages include:

Increased Efficiency and Productivity

By automating tasks, optimizing workflows, and providing real-time visibility into operations, a management warehouse system can dramatically improve efficiency and productivity. This translates to faster order fulfillment, reduced labor costs, and increased throughput.

Reduced Costs

A management warehouse system helps to minimize waste, optimize inventory levels, and reduce errors, leading to significant cost savings. These savings can be realized in areas such as:

- Inventory Holding Costs: Reducing excess inventory and minimizing obsolescence.

- Labor Costs: Automating tasks and improving employee productivity.

- Shipping Costs: Optimizing order fulfillment and reducing shipping errors.

- Damage and Loss: Minimizing product damage and loss through improved handling and tracking.

Improved Accuracy and Inventory Control

Real-time inventory tracking and automated data capture minimize errors and ensure accurate inventory control. This helps to prevent stockouts, reduce discrepancies, and improve order accuracy.

Enhanced Customer Satisfaction

Faster order fulfillment, improved accuracy, and real-time order tracking contribute to enhanced customer satisfaction. Happy customers are more likely to return and recommend your business to others. [See also: Customer Relationship Management Strategies]

Better Decision-Making

A management warehouse system provides valuable data and insights that can be used to make informed decisions. This includes:

- Demand Forecasting: Predicting future demand to optimize inventory levels.

- Performance Analysis: Identifying areas for improvement and tracking progress.

- Resource Allocation: Optimizing the allocation of resources such as labor and equipment.

Implementing a Management Warehouse System: A Step-by-Step Guide

Implementing a management warehouse system can be a complex undertaking, but by following a structured approach, you can ensure a successful implementation. Here’s a step-by-step guide:

Assess Your Needs

Start by thoroughly assessing your current warehouse operations and identifying areas for improvement. Consider factors such as:

- Inventory Volume and Turnover: How much inventory do you handle, and how quickly does it turn over?

- Order Complexity: How complex are your orders, and how many items do they typically contain?

- Shipping Requirements: What are your shipping requirements, such as delivery speed and destination?

- Budget: What is your budget for implementing a management warehouse system?

Select the Right WMS Software

Choose a WMS software that meets your specific needs and budget. Consider factors such as:

- Functionality: Does the software offer all the features you need?

- Scalability: Can the software scale as your business grows?

- Integration: Does the software integrate with your existing systems, such as your ERP and accounting software?

- Vendor Reputation: Does the vendor have a good reputation and provide reliable support?

Optimize Your Warehouse Layout

Review your warehouse layout and make any necessary adjustments to optimize efficiency. This may involve:

- Reorganizing Storage Locations: Grouping similar items together and optimizing storage density.

- Improving Material Flow: Minimizing travel distances and eliminating bottlenecks.

- Creating Dedicated Zones: Designating specific areas for receiving, put-away, picking, packing, and shipping.

Implement the System

Work with your WMS vendor to implement the software and configure it to your specific needs. This may involve:

- Data Migration: Transferring your existing data into the new system.

- System Configuration: Customizing the software to match your workflows.

- Testing: Thoroughly testing the system to ensure it is working correctly.

Train Your Employees

Provide comprehensive training to your employees on how to use the new system. This should include:

- System Navigation: Teaching employees how to navigate the software and access the information they need.

- Data Entry: Training employees on how to accurately enter data into the system.

- Troubleshooting: Providing employees with the knowledge to troubleshoot common issues.

Go Live and Monitor Performance

Once the system is implemented and your employees are trained, you can go live. Monitor performance closely and make any necessary adjustments to optimize efficiency. [See also: Key Performance Indicators for Warehouse Management]

Future Trends in Management Warehouse Systems

The field of management warehouse systems is constantly evolving, with new technologies and trends emerging all the time. Some key trends to watch include:

Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML are being used to optimize various aspects of warehouse operations, such as:

- Demand Forecasting: Predicting future demand with greater accuracy.

- Route Optimization: Optimizing delivery routes to minimize travel time and fuel costs.

- Predictive Maintenance: Predicting equipment failures and scheduling maintenance proactively.

Robotics and Automation

Robotics and automation are becoming increasingly prevalent in warehouses, with robots being used for tasks such as:

- Picking and Packing: Automating the retrieval and packaging of items.

- Sorting and Conveying: Automating the movement of goods within the warehouse.

- Inventory Management: Using drones to scan and track inventory.

Cloud-Based WMS

Cloud-based WMS solutions are becoming increasingly popular due to their scalability, affordability, and ease of deployment. Cloud-based WMS offers several advantages, including:

- Lower Upfront Costs: No need to invest in expensive hardware and software.

- Scalability: Easily scale your system as your business grows.

- Accessibility: Access your system from anywhere with an internet connection.

Internet of Things (IoT)

IoT devices are being used to collect data from various warehouse equipment and sensors, providing real-time visibility into operations. This data can be used to:

- Monitor Temperature and Humidity: Ensuring optimal storage conditions for sensitive products.

- Track Equipment Usage: Optimizing equipment utilization and scheduling maintenance.

- Improve Safety: Monitoring worker safety and identifying potential hazards.

Conclusion

A well-implemented management warehouse system is essential for optimizing efficiency, reducing costs, and improving customer satisfaction. By understanding the core components of a management warehouse system, implementing a structured approach to implementation, and staying abreast of future trends, you can transform your warehouse into a competitive advantage. Embracing a modern management warehouse system isn’t just about keeping up; it’s about leading the way in a dynamic and demanding marketplace. The right system, tailored to your specific needs, will provide the visibility and control necessary to thrive in today’s competitive landscape, ensuring your warehouse operates at peak performance and contributes directly to your overall business success. Investing in a robust management warehouse system is an investment in your future.